Concrete is one of the most widely used construction materials, valued for its strength, cost-effectiveness, and versatility. Yet, untreated concrete floors are prone to dusting, wear, and surface deterioration under heavy use. This is where a lithium concrete densifier makes a remarkable difference, not only by increasing abrasion resistance but also by enhancing the natural gloss of polished floors.

At Noble Alchem, we specialize in high-purity silicate solutions designed to maximize floor performance for industrial, commercial, and residential applications. Let’s explore how lithium densifiers work and why they are the preferred choice for creating strong, durable, and glossy concrete floors.

What is a Lithium Concrete Densifier?

A lithium concrete densifier is a liquid solution formulated with lithium silicate. When applied, it penetrates deep into the concrete pores and reacts chemically with free calcium hydroxide. This reaction forms calcium silicate hydrate (C-S-H)—the same compound that gives concrete its strength during curing.

The result is a denser, harder surface that resists abrasion, reduces dusting, and provides a smoother base for polishing.

How Lithium Densifiers Improve Abrasion Resistance

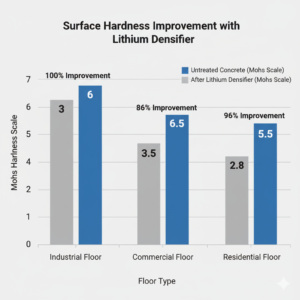

Abrasion resistance is critical for floors exposed to constant foot traffic, heavy machinery, or industrial activity. Ordinary untreated concrete can flake, dust, and wear out quickly. Lithium densifiers address these challenges in several ways:

- Deeper Penetration

- Lithium molecules are smaller than sodium or potassium, allowing them to penetrate more deeply into the concrete.

- This ensures stronger bonding and improved durability at the core.

- Harder Surface Formation

- By creating additional C-S-H within the concrete matrix, the surface becomes significantly harder and more resistant to scratches, scuffs, and wear.

- Reduced Dusting and Micro-Cracking

- Densifiers fill capillaries and pores, minimizing the weak points where dust and cracks typically form.

- This ensures cleaner, safer, and low-maintenance floors.

- Long-Lasting Performance

- Unlike surface coatings that peel or wear off, lithium densifiers chemically bond with the concrete, ensuring permanent improvement in abrasion resistance.

How Lithium Densifiers Enhance Gloss and Shine

Polished concrete has become a preferred flooring option in warehouses, showrooms, retail outlets, and modern homes. A lithium concrete densifier plays a key role in achieving and maintaining a glossy finish:

- Smooth Base for Polishing

- By filling pores and creating a harder surface, densifiers provide an ideal base for mechanical polishing.

- Higher Light Reflection

- Densified concrete reflects light more effectively, resulting in a sleek, mirror-like finish.

- Stain and Spill Resistance

- The densified surface reduces porosity, making it more resistant to stains, oils, and chemicals.

- This helps maintain the gloss over time with minimal maintenance.

- Enhanced Aesthetics

- The improved shine elevates the look of commercial spaces, retail showrooms, and residential interiors, creating a premium feel.

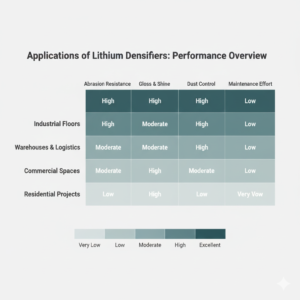

Applications of Lithium Concrete Densifiers

- Industrial floors – withstand heavy equipment and traffic.

- Warehouses & logistics hubs – minimize dust and maintenance.

- Commercial spaces – enhance aesthetics with polished, glossy finishes.

- Residential projects – long-lasting, stain-resistant, polished floors.

Why Choose Noble Alchem’s Lithium Concrete Densifier?

At Noble Alchem, our lithium silicate solutions are engineered for:

- High purity and consistency → ensuring reliable performance across projects.

- Deep penetration technology → delivering maximum abrasion resistance.

- Eco-friendly, low VOC formulation → safe for the environment and sustainable construction.

- Proven results → used in industrial, commercial, and residential flooring across India and global markets.

A lithium concrete densifier is more than just a surface treatment—it’s a long-term investment in strength, performance, and beauty. Lithium densifiers transform ordinary concrete into a durable, polished, low-maintenance flooring solution by improving abrasion resistance and enhancing gloss.

FAQs on Lithium Concrete Densifiers

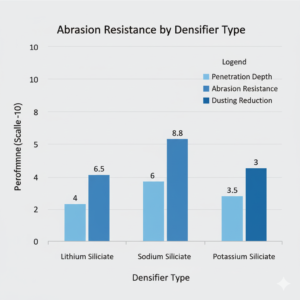

Q1. How is a lithium concrete densifier different from sodium or potassium densifiers?

Due to their smaller molecule size, lithium densifiers penetrate deeper, ensuring stronger bonding and longer-lasting results than sodium or potassium silicates.

Q2. Do lithium concrete densifiers make floors completely stain-proof?

While they significantly reduce porosity and improve resistance to spills and stains, combining densifiers with sealers offers the best protection for high-traffic or chemical-exposed areas.

Q3. Can lithium densifiers be applied to old concrete floors?

Yes. Lithium densifiers work effectively on both new and existing concrete floors, improving hardness, reducing dusting, and preparing surfaces for polishing.

Q4. How long does it take for a lithium densifier to show results?

Initial hardening begins within hours, but full reaction and benefits, including gloss enhancement, are visible after 24–48 hours of curing and polishing.

Q5. Are lithium concrete densifiers eco-friendly?

Yes. Noble Alchem’s lithium silicate densifiers are water-based, non-toxic, low in VOCs, and safe for sustainable construction practices.

Looking for the best lithium concrete densifier to strengthen and beautify your floors?

Trust Noble Alchem—a leader in silicate-based construction solutions.

Contact us today to explore our full range of densifiers and bring lasting durability and shine to your concrete floors.

Noble Alchem – Strengthening Floors, Shaping Construction Futures.