We manufacture potassium, sodium, lithium and mixed silicates for welding electrode.

Noblealchem is established in 1986 and it forges in the manufacturing of wide ambit of chemical products, which also includes silicates like lithium, potassium, sodium silicates which are used for welding purposes. Silicates function not only as simple binder but additionally it is examined as the main welding additives. The demand for silicates for welding electrodes hikes when premium quality welding material is used. Our company produces and supplies superior quality silicates for producers of welding electrodes.

Manufacturing of many industrial elements is based on Welding. To deliver the best quality industrial products, the quality of welded joints has to be perfect, which depends on welding rods and to do so, the manufacturer has to carefully select the welding additives to the composition.

Welding rods consist of various mineral and metal powders which are bound together Silicates. Silicates act as both a binder and a fluxing agent.

Silicates are often the main welding additives and their function widely exceeds that of a simple binder. Lithium silicate is used for low emission electrodes. Potassium silicate is used for soft,low-alloyed steels whereas for high-alloyed steels potassium lithium is used. In the case of special high-alloyed steels, sodium lithium silicate is used to melt. The soluble silicates are sodium, potassium silicates which are hygroscopic materials. These coatings are proposed as having great mechanical strength. Potassium, sodium silicates are favored as it reduces spattering, improves slag mobility and reinforces wear resistance in high-temperature alignments that require chemical stability. We manufacture Potassium, Sodium, Lithium and Mixed Silicates of the highest purity.

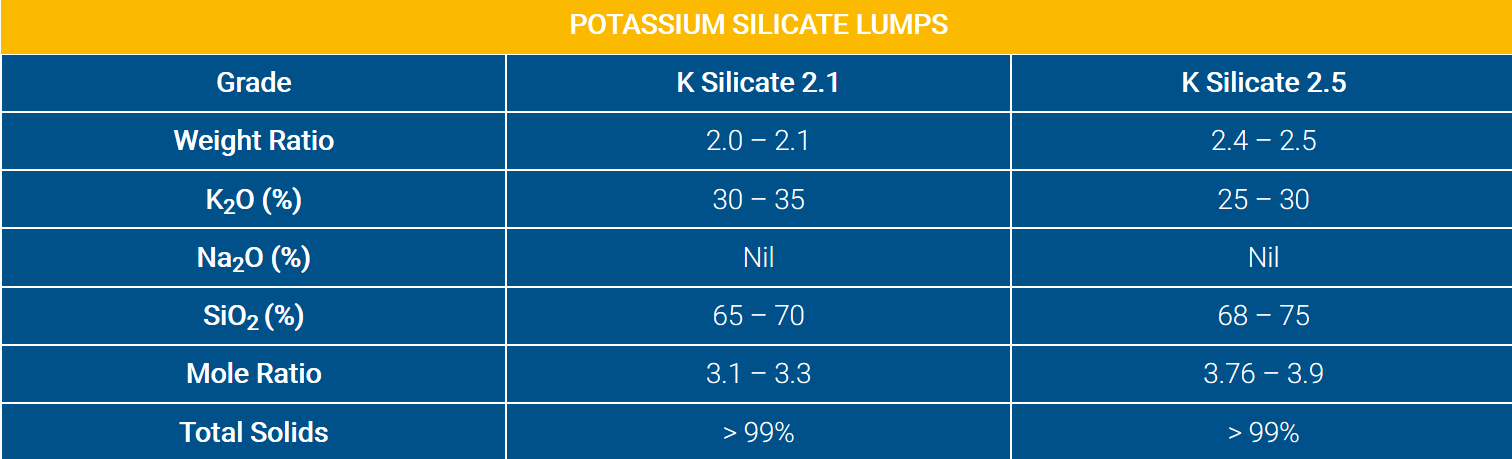

Silicates are available as liquids, solids (lumps) and powders with a different type of blends of potassium, lithium and sodium elements. Smooth Extrusion, Quiet Burning, Low Arc Spattering, and slag formation are some of the attributes, which depend upon the quality of SILICATES.

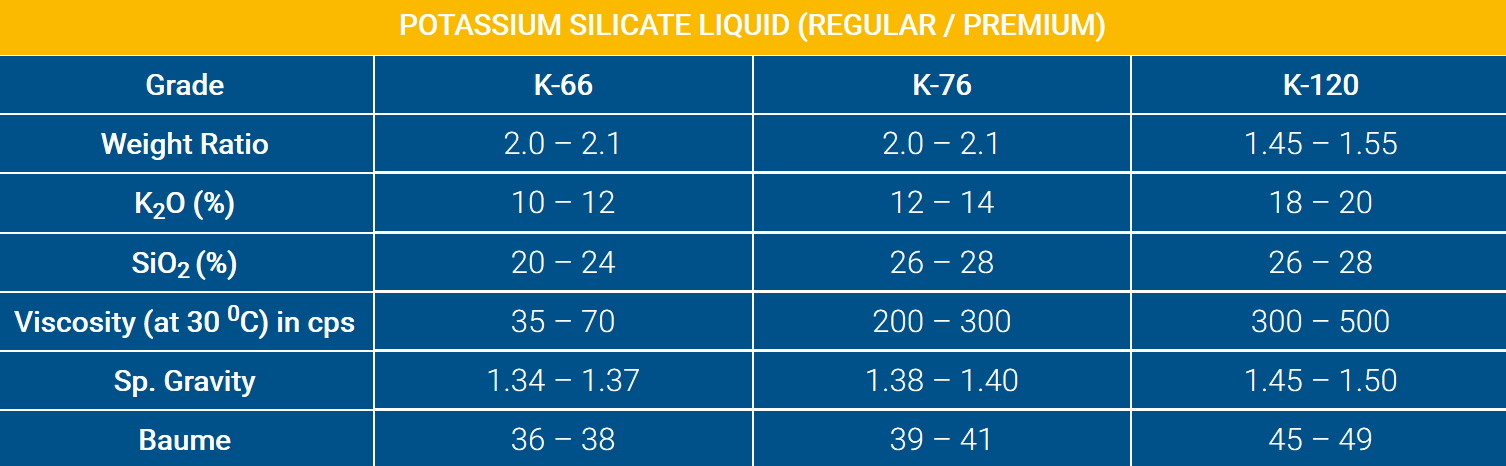

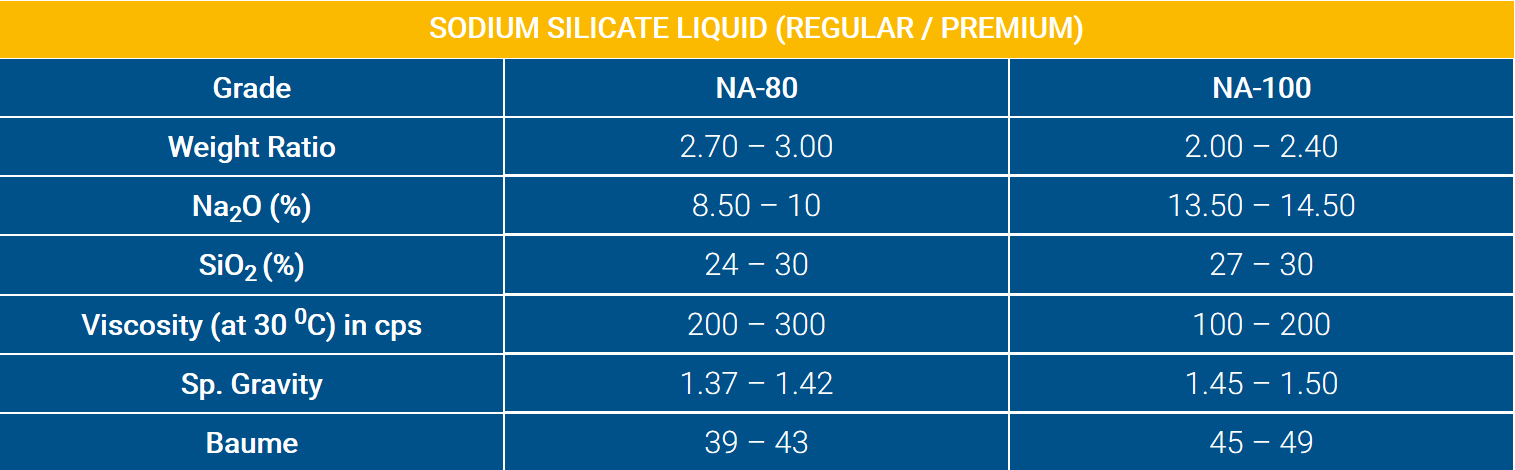

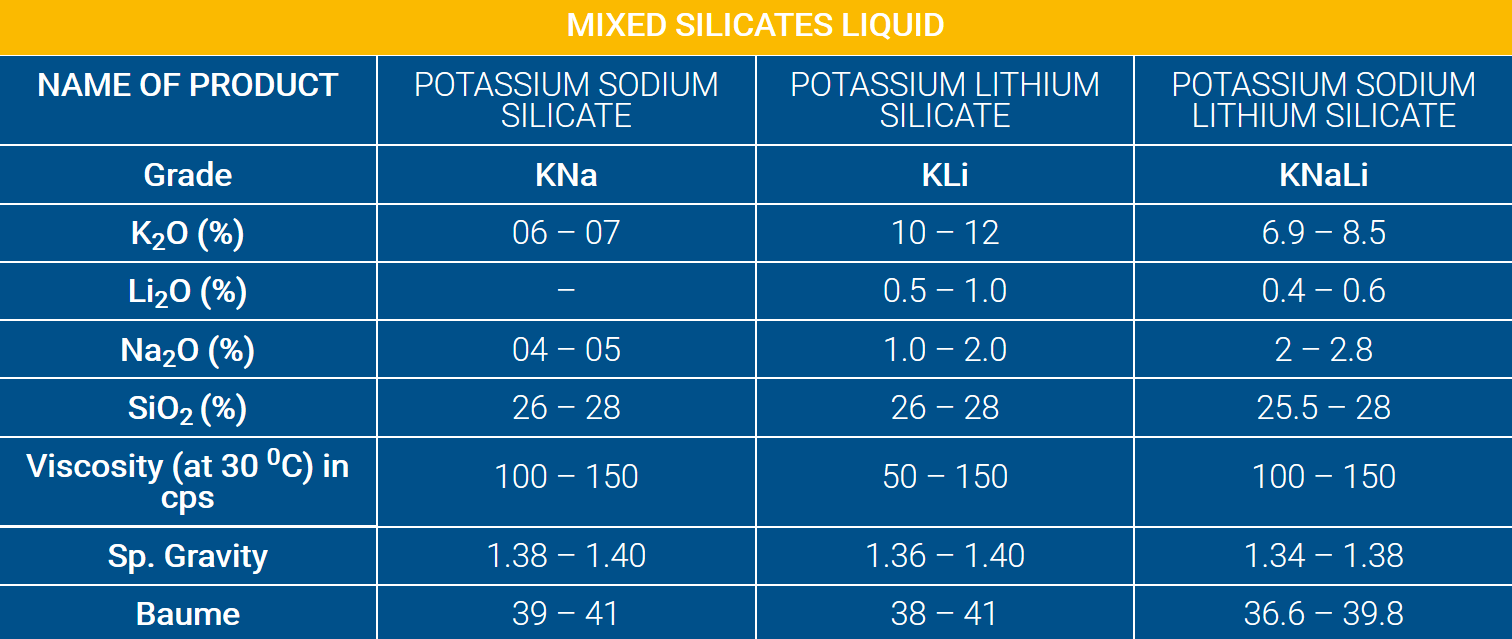

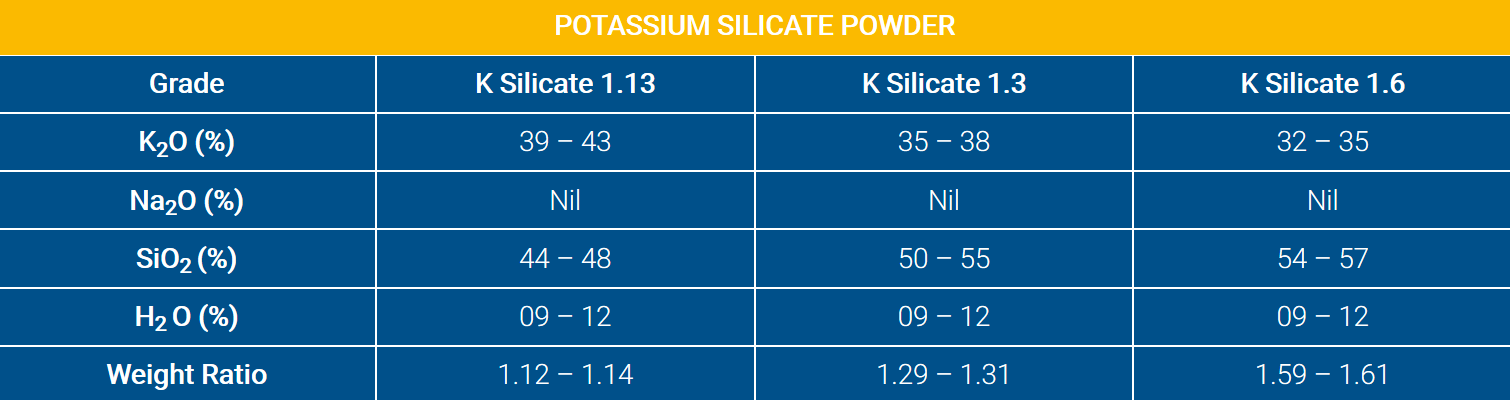

TECHNICAL SPECIFICATIONS OF VARIOUS SILICATES FOR WELDING ELECTRODE

We can customize as per client’s specifications also

We manufacture Potassium, Sodium, Lithium and Mixed Silicates for welding electrodes of the highest purity. Our experienced specialists develop customized solutions to meet the requirement of our customers. Noble adds lithium to the welding rods chiefly in the form of lithium fluoride and lithium silicates. We use gradient or quash material to destabilize the lithium-containing arc plasma and to provide it higher voltage. We aim at manufacturing supreme quality welding consumables. Our prime concern is to provide welding electrode coating that is free from any disadvantages of current welding electrode coating and to fulfill variegated requirements.noble is bracketed among the high-standing manufacturers of welding electrode across the globe.

Our experienced specialists develop customized solutions to meet the requirement of our customers.

We not only manufacture silicates for welding but also manufacture potassium, sodium & mixed Titanates for welding.

PACKING OPTIONS

Tanker load

JUMBO BAGS

Drums

IBC

Flexi Tank

ISO Tank Container