Concrete Finishing & Floor Polishing

Silicates for Flooring

Lithium concrete densifier

lithium silicate concrete sealer

polished concrete densifier

cement floor polish liquid

densifier for concrete floors

Noble Silicates, starting from high-end lithium based silicates to economical potassium & sodium silicates are usually used in various concrete and finishing applications. These silicates are used as floor hardener and polisher in industrial sheds, corporate buildings, warehouses etc. to reduce dust formation and increase the durability of the surface.

Our advanced lithium silicate densifier offers both durability and aesthetics to concrete floors and surfaces. Specially formulated for professional use, this lithium silicate concrete sealer / densifier penetrates deep into the surface, creating a robust reaction that fortifies the surface from within.

Use of Lithium concrete densifier in cement floor polish liquid

Lithium concrete densifier is a vital material used in cement floor polish liquid giving protection and longevity to your concrete surfaces. It transforms ordinary concrete into a hardened substrate, capable of withstanding abrasion and wear over time. Moreover, the polished concrete densifier ensures that the concrete retains its luster and polish for years to come.

Manufacturer of densifier for concrete floors

Noble Alchem is the leading provider of lithium silicate densifier for concrete floors. It is an exceptional material for concrete surface enhancement. Our lithium concrete densifier produces robust and quality concrete surfaces, making it the preferred choice for the architects, contractors and companies working in the construction sector.

Potassium and sodium silicate application to concrete admixtures

Adding potassium or sodium silicate to concrete admixtures accelerates the hydration and reduces the setting time. Construction of building foundations, underground tunnels and railroads are the biggest examples of usage of silicates.

For concrete floors, unlike epoxy’s & other coatings, different silicates like lithium, potassium, sodium or mixed silicate liquids have many attributes like :

- Easy application,

- Quick drying

- No maintenance

- Very Easy to clean

- Eco-friendly

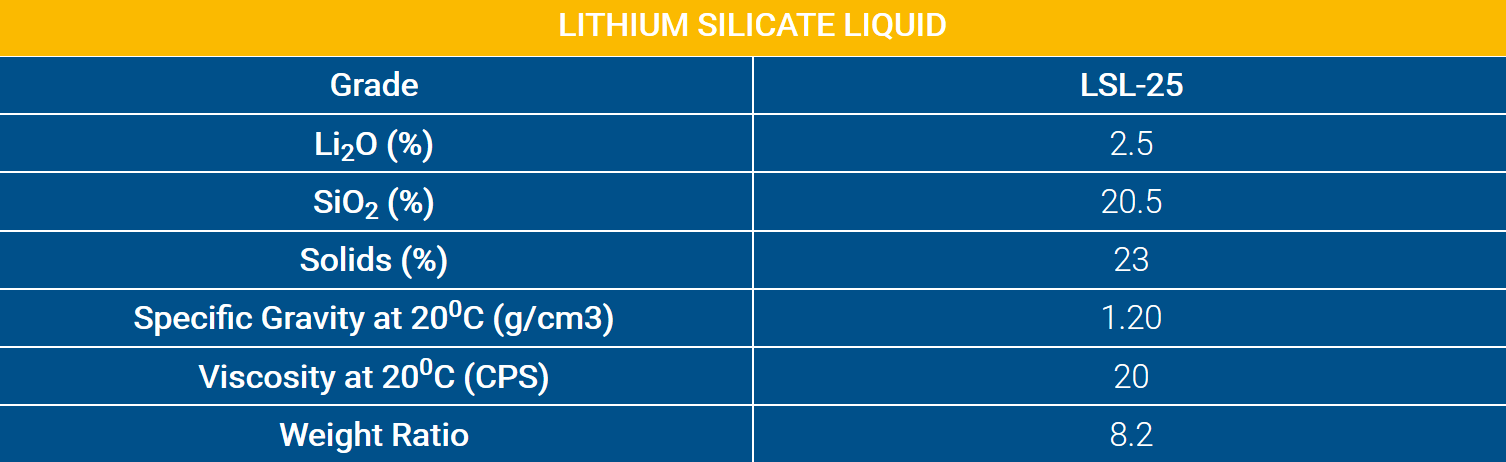

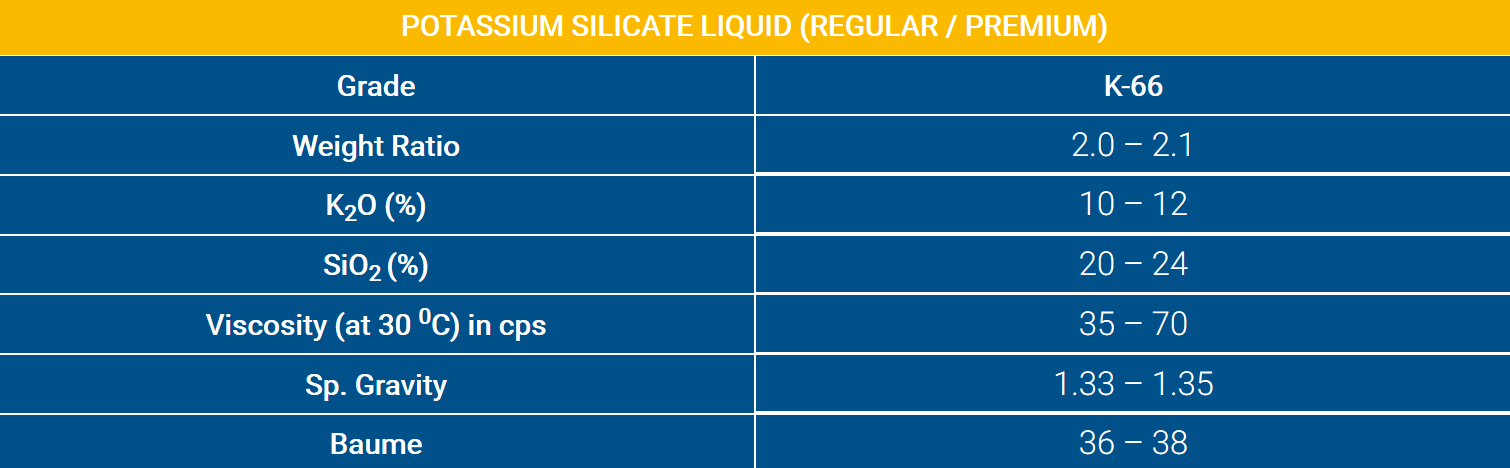

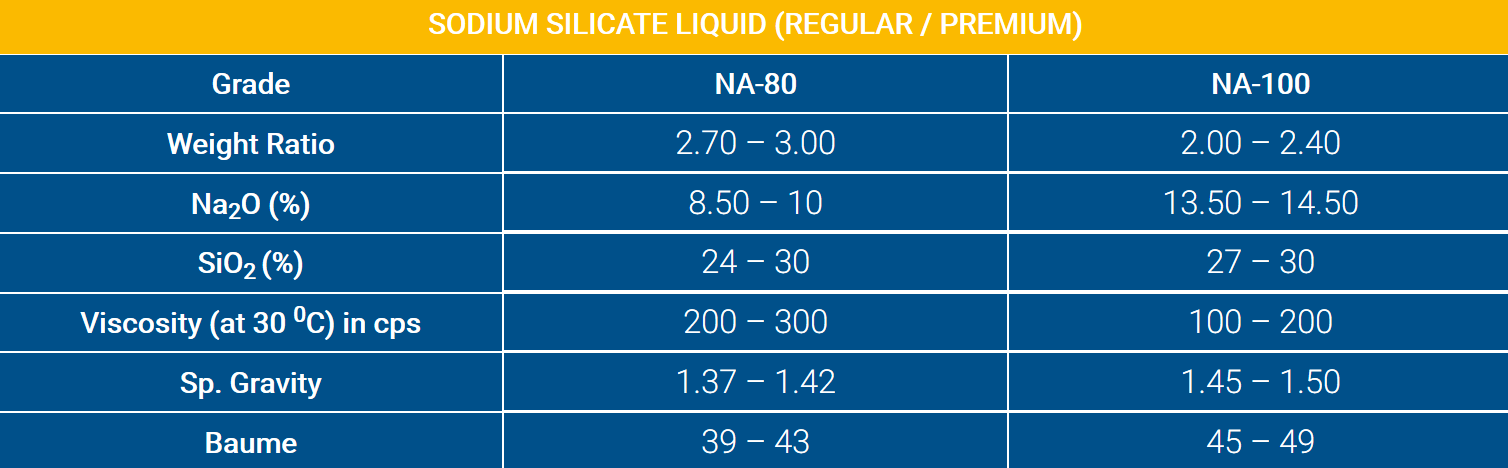

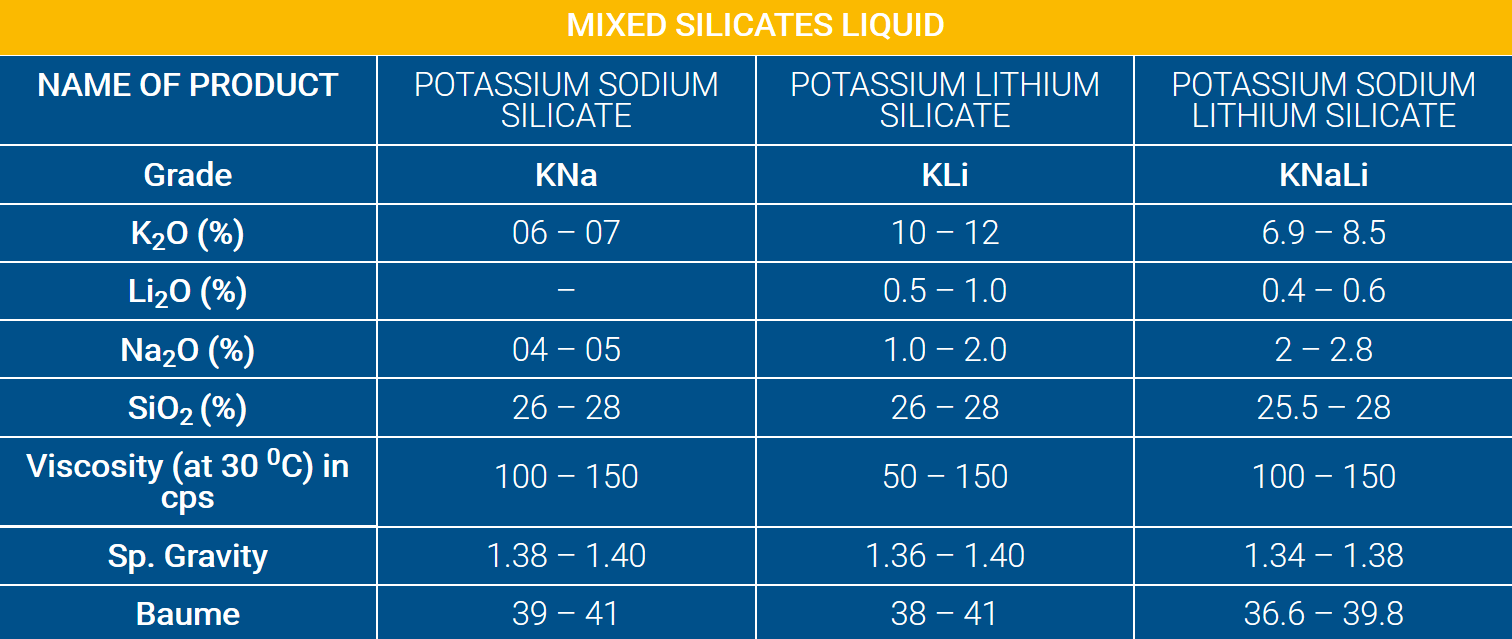

TECHNICAL SPECIFICATIONS

We can customize as per client’s specifications. We also manufacture Silicates for Paints.

PACKING OPTIONS

Tanker load

ISO Tank Container

Drums

IBC

Flexi Tank